Whole dry low fat corn flour manufacturing fructose syrup technology is a break through in corn deep processing field in recent years.

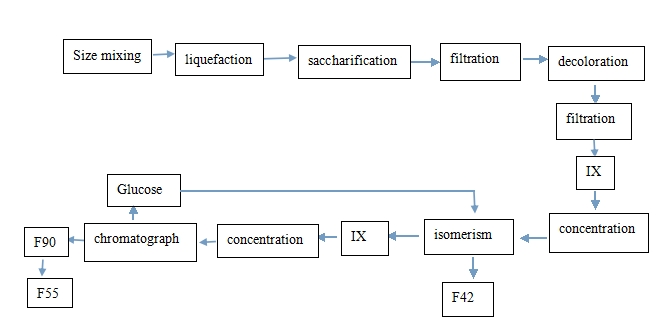

The dry milling technology produces no pollution water during hulling, degerminating, deproteinizing and defatting process. Then the corn is milled into 70-80 mesh flour to meet requirement of producing glucose. Corn flour get into multiple liquid ejection process after size fixing, turning corn flour into fine paste, filtering and separating corn sugar residue and syrup. The 40-50% protein feed is dried, crushed, sifted to reach standard and go to market. The wet cake can directly be sold to livestock plants. Liquid sugar goes into saccharification process to transform into glucose. The product is adjusted to F42, F55, F90 according to clients after twice decoloration, Ion Exchange and multiple-effect concentration, isomerism, chromatograph so as to meet market demands.

The technology is ideal for corn deep processing project with low power consumption, non-pollution and beneficial byproducts.

Our line is built upon innovation of many patented technologies of our company and foreign technology instead of repetition of traditional method, which is a breakthrough of dry milling and development of syrup manufacture.

1. It uses double -part ejection and liquefaction technology with high temperature liquifying enzyme to separately control the temperature and efficiently deactivate enzyme. The starch is fully liquified and protein is completely degenerated without recovery. DE is controlled within 10-17%,starch yield is increased from 55-60% to 85%.

2. Vacuum flashing is adopted to separate starch and residue at a high temperature. Little starch is left in the residue, the protein is degenerated to a large amount of flocculation. Over 90% of the protein and fat are separated from maltose liquid.

3. Twice reverse flow decoloration technology keeps a long time absorption of protein, fat, ash and organic impurities. It guarantees good color and long shelf period by utmost reducing affection of protein and fat to sugar.

4. Three level Ion Exchange column completely removes ash to increase maltose boiling temperature, reducing color change.

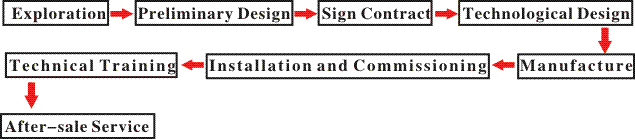

Send us a message, we will contact you soon.

Related News: