20TPD Maize Milling Plant with dry milling method adopts the most advanced flow-line design of corn fine and deep processing with new drying milling method, and produces products which meet or surpass the national standard. The production line has the following advantages:advanced technology, fine and professional equipments quality, scientifc arrangement, low power, excellent flour with high recovery rate. The product is widely used in food plant, beer plant, sugar plant and so on. The core equipments gain national patent.

The production line has the following advantages:advanced technology, fine and professional equipments quality, scientifc arrangement, low power, excellent flour with high recovery rate. The product is widely used in food plant, beer plant, sugar plant and so on. The core equipments gain national patent.

1.Automatic Roller Mill.

2.Reasonable Design.

3.Easy operation.

4.Low energy consumption.

The two grinding disc full of alveolus is running and grinding. Through mechanical force of roll grinder, the germ, epidermis and endosperm are neatly separated. The crusher ensures that a corn kernel with nutrient content remains after the milling process of endosperm is completed.

Type: 20T

Power:72kw

Power consumption: 58-60kw/h

Capacity: 20TPD

Dimension of workshop(L*W*H, M): 20*5*5 for line structure, and 16*5*6 for steel structure.

Final products technical index:

|

Model |

6FYDCT-20 |

|

Production Capacity (T/24h) |

20 |

|

Main machines and

processing techniques |

High efficiency vibration sifter, Destoner, Damper, Peeling crusher, Embryo separator, Roller mill, Grading machine, Super- micro-particle pulverizer |

|

Products and

extraction rate (%) |

Corn flour: 40-50%

Corn grits: 35-40%

Corn bran, coarse fodder:10-12%

Embryo: 8-10%

It can produce fine corn flour (all through 100M fiter) |

|

Products quality index |

Sand content: ≤0.02%

Fat content: ≤2.5%

Magnetic metal content: ≤0.003%

Moisture content: ≤13.5-14.5% (based on the raw corn according with national standard for raw grain storage) |

|

Power required (kW) |

Around 72 |

|

Size of workshop(L×W×H, m) |

20×5×5 |

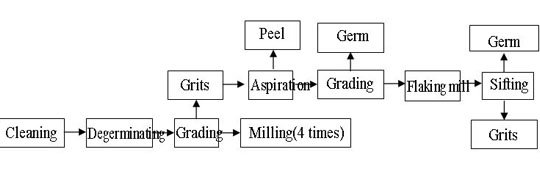

1. Provide Precise design Proposal: Including Detailed Quotation List, CAD Flow Chat, Technological Index, Installation Diagram,and provide installed production line video and photos for customers reference.

2. Delivery Goods: Provide standard shipping wooden package, full set of equipments photos before and after packing goods.also, full set of shipping documets sent by post.

3. Installation: Engineers is available to install machine oversea.

4. Quality Guarantee Term: 12 Months.

5. After-sales service: Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which are caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

Send us a message, we will contact you soon.

Related News: