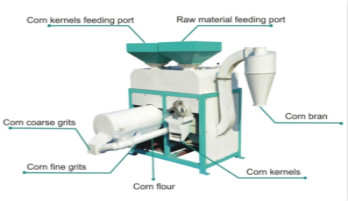

YTZSF28-30 corn peeling, grits& milling machine is a new and small assembled unit which can be used for pealing, polishing, miling, sifting and winnowing. It is widely used in small and medium grain processing plants for producing corn kernel, medium grits, small grits and corn flour. By using YTZSF28-30, you will get the maximum profits with the little cost.

YTZSF28-30 corn peeling, grits& flour making machine set is newly developed, it integrates peeling, polishing,degermination, grits making, grading and milling together, can produce corn kernel, medium grits, small grits and corn flour. It can be sued in corn peeling and grits making, wheat and other grains peeling and flour milling. Corn peeling, grits & flour making machine is your best choice.

1, YTZSF28-30 corn peeling, grits& milling machine has multi-purposes, compact structure and high efficiency. It is the ideal equipment for the corn processing enterprises, wheat and rice processing plants.

2, Materials are high quality steel.

3, Easy operation and maintenance. It will save you much labor cost and maintenance cost.

4, Weel sealed without flying dusts. It prolongs the working lifte of corn peeling, grits and milling machine greatly.

| Type |

Capacity (kg/h) |

Pelling speed (r/min) |

Milling speed (r/min) |

Grading speed (r/min) |

Reted voltage (V) |

Power (kw) |

Weight( kg) |

Dimension (mm) |

| YTZSF28-30 | 500 | 970 | 3024 | 576 | 380 | 11 | 428 | 1900×1500×1460 |

1.We provide all the technical materials and drawings as the contract; compile and supplement operation manual according to the final commissioning results.

2.We offers on-site training service according to progress of the project, installing, trying operation and production of the whole line as it is required on the technical materials and drawings.

3.We gives training of installation, commissioning, use and maintenance

4.During warranty period, our company will provide an answer or staff within 4 hours once receiving feedbacks about quality of the products.

5. Beyond warranty period, we will provide paid service for improvement of technology, maintenance of the machine or offer of the spare parts.

Send us a message, we will contact you soon.

Related News: